VETRODOMUS S.p.A., founded in 1962 by the Pastore family, stands out on the international market as an excellence in flat glass processing.

In the production plant, of about 14,000 square meters located in Brescia, with the help of technically advanced systems and about 75 employees, products are always made up to the demands of the market, maintaining a quality standard of the highest level.

Read more about VETRODOMUS S.p.A.

VETRODOMUS S.p.A. is able to apply its know-how to production in order to meet the requests for tailor-made glass architecture projects of international scope. The aesthetic and structural properties of flat glass are generated by the various processes of its transformation: from the arrival of the raw material that supplies the Glass sheets Warehouse, to the different processing and transformation paths required. Each processing phase takes place in the Brescia plant, through different production lines, thus allowing us to produce a multiple and diversified offer. To carry out tailor-made projects of excellence, VETRODOMUS S.p.A. realizes:

Discover some projects made with glass processed by VETRODOMUS S.p.A.

The entire production of VETRODOMUS S.p.A. it is managed internally in our production plant in Brescia. The exclusive supply of top quality material corresponding to the CE regulations includes: Clear Float Glass, Colored Float, Laminated Glass, Glass coated with selective and low emissivity coating.

To learn about the glass processing of VETRODOMUS S.p.A, follow the link to the PRODUCTION page

Our warehouse provides a considerable storage capacity for transparent, extra-clear and coated material.

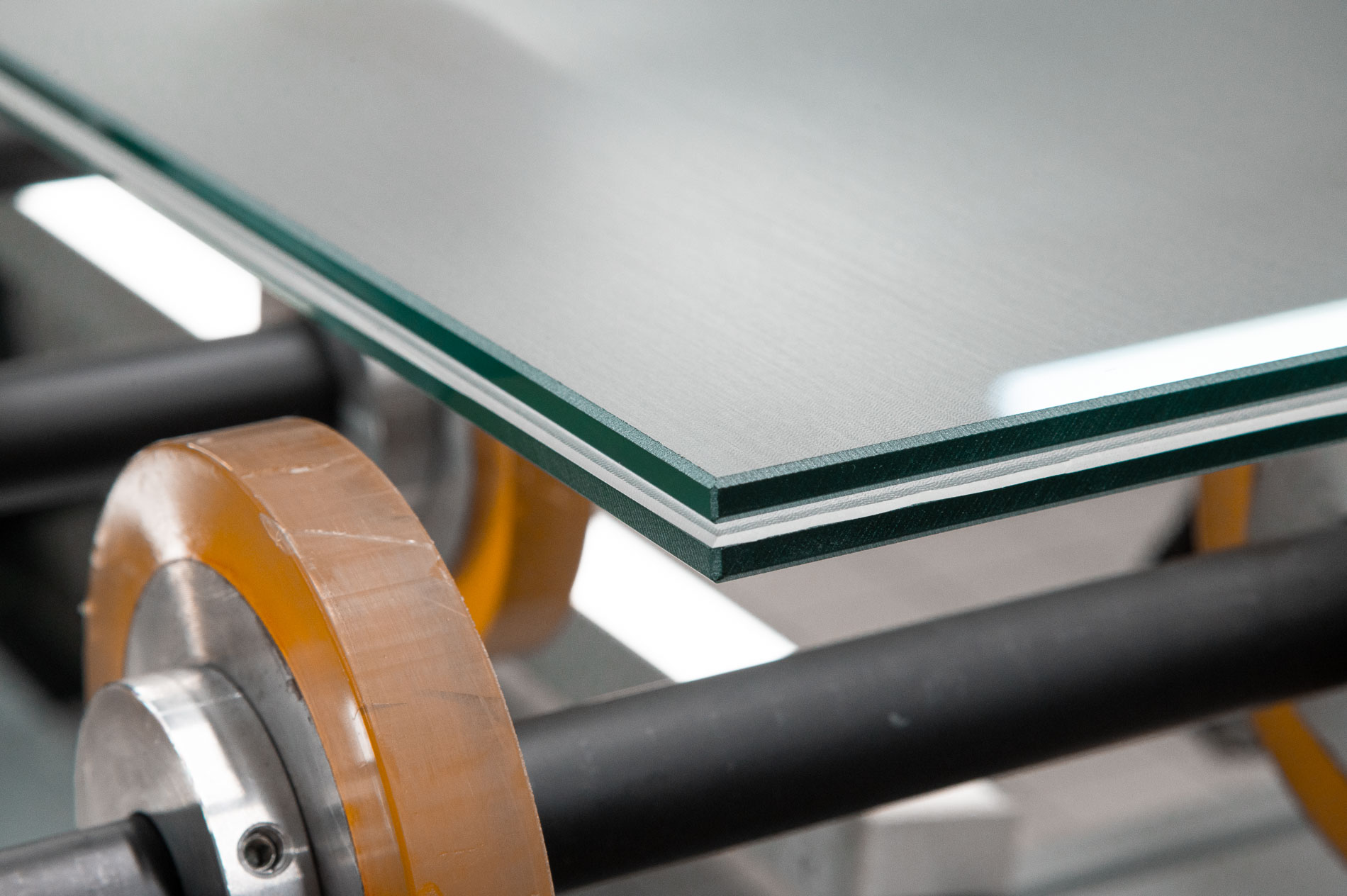

Cutting is the first operation of the entire production process, the goal is to dissect the large slab into individual pieces to size, trying to discard the least amount of material.

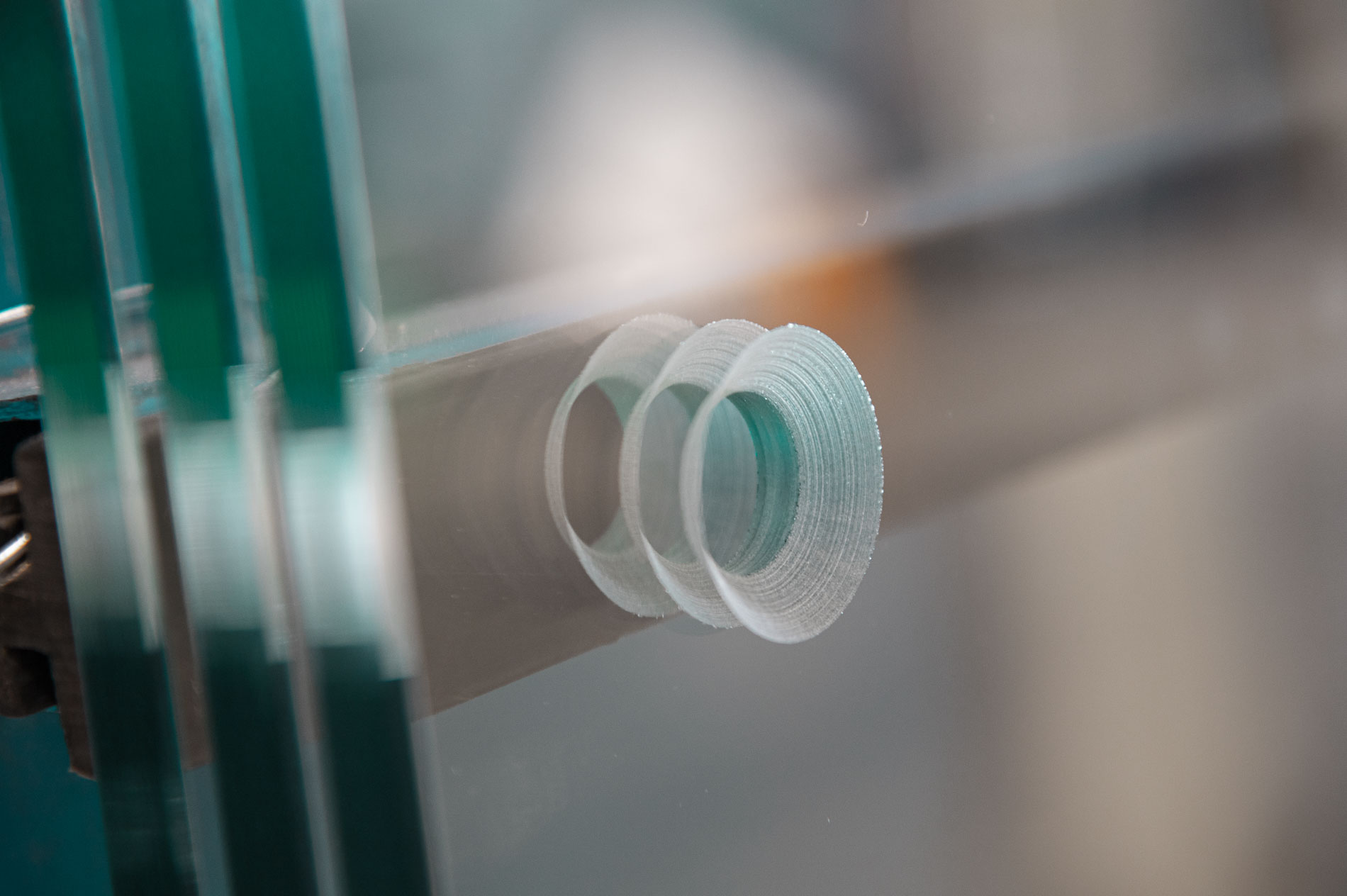

Grinding is the operation that allows you to eliminate all the irregularities of the cut in the entire perimeter of the glass.

Enamelling is the process by which a total coverage of one face of the glass is carried out through the use of a roller or spray.

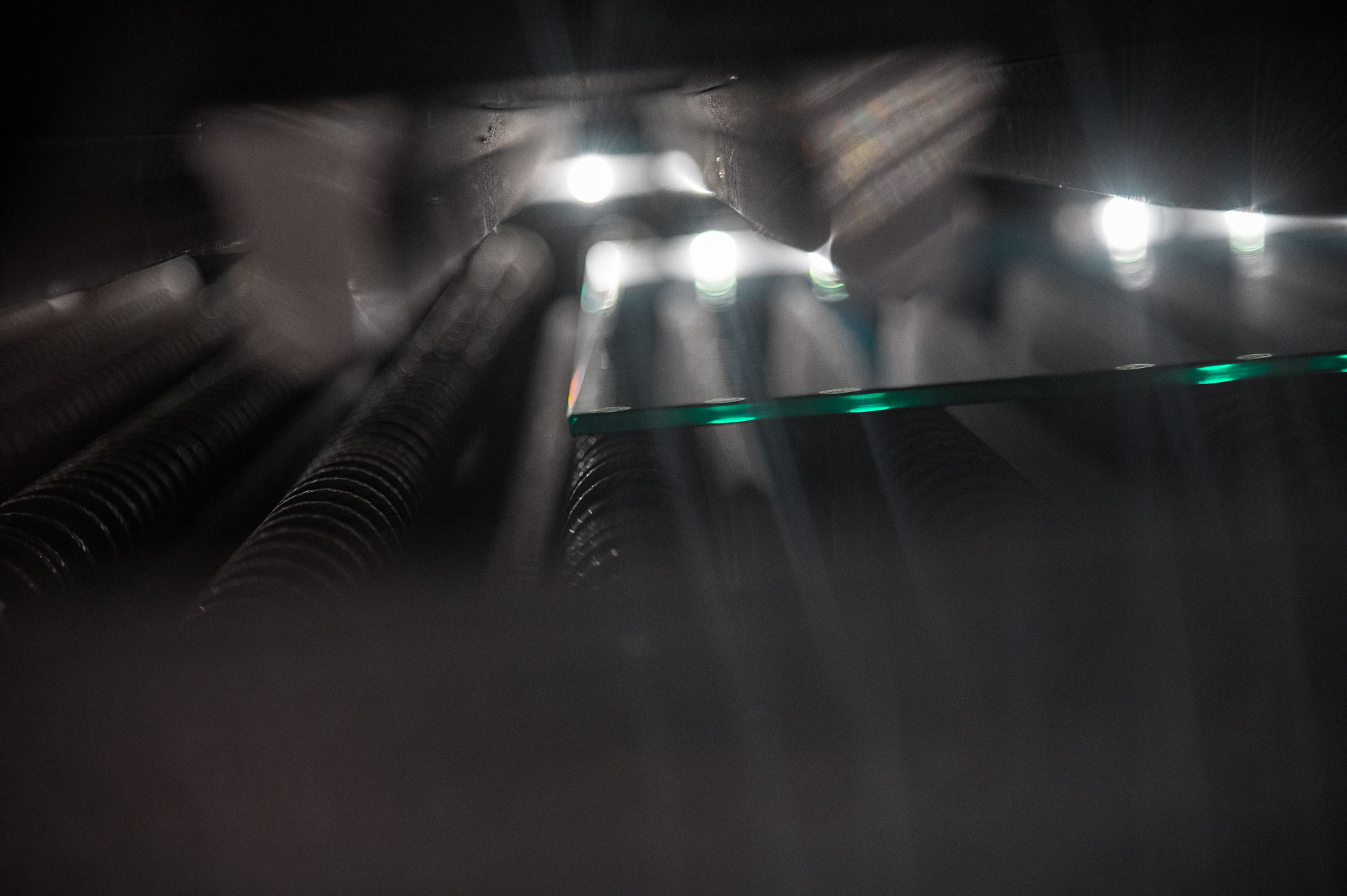

The tempering process is carried out for applications where certain levels of safety are required.

The lamination process is carried out by coupling two or more single sheets of glass, interposing plastic interlayers (PVB, SG), through a process of heating and controlled pressure.

The insulating glass is a glass composed of two or more sheets of glass separated by a gap of air or gas (Argon or Krypton).

Each department carries out specific tests relating to the different processing stages.

To learn about the glass processing of VETRODOMUS S.p.A, go to the page

VETRODOMUS S.p.A. is committed on several fronts to keep the quality level of glass processing high. The certifications obtained over the years and the investments in an Industry 4.0 perspective, have led the company to international recognition as a reliable partner for glass creations in construction sites in Europe, America and Africa.

Discover the integrated system for quality and certifications of VETRODOMUS S.p.A.

VETRODOMUS S.p.A. collaborates in the implementation of numerous Green architecture and building projects, transforming flat glass for the execution of major works around the world.

Discover the international glass architecture projects VETRODOMUS S.p.A.

VETRODOMUS S.p.A. is an important reality in the world of global glass production.

In this section you can find industry news and insights. Read the news of VETRODOMUS S.p.A. (